Leonardo RF, Fire-resistant ceiling radiant system

- Surface Ceiling

- Type Single family residence, Multi-family residence, Services

WSP Lab certified yield

Adductions inserted in the panel

Fire reaction test according to UNI EN 13501-1 and EN 13964

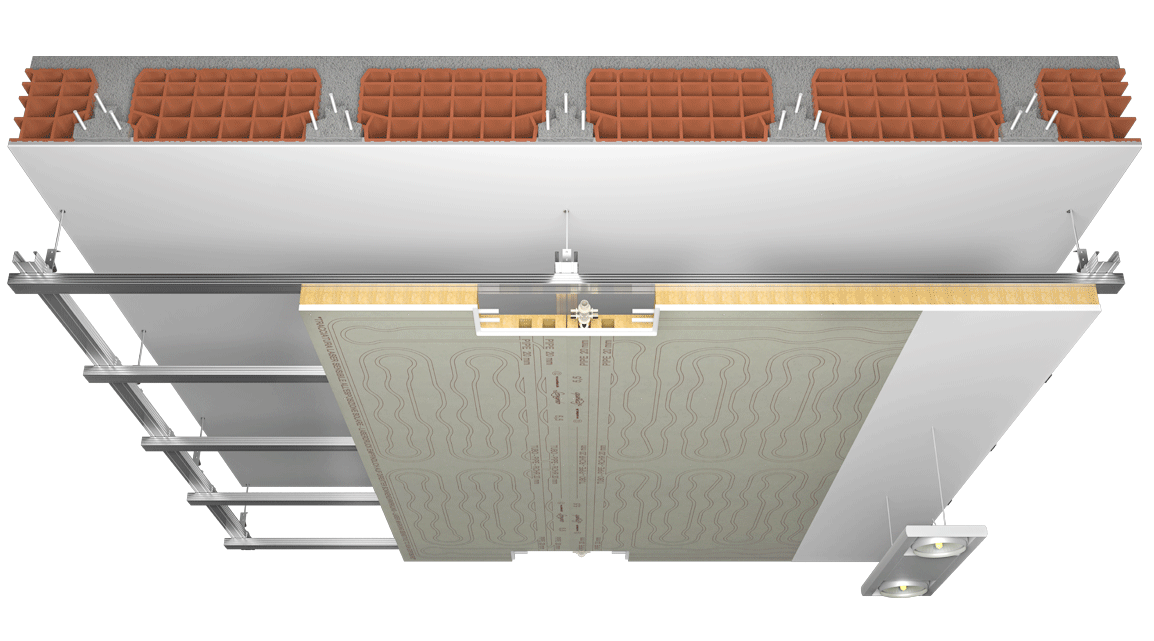

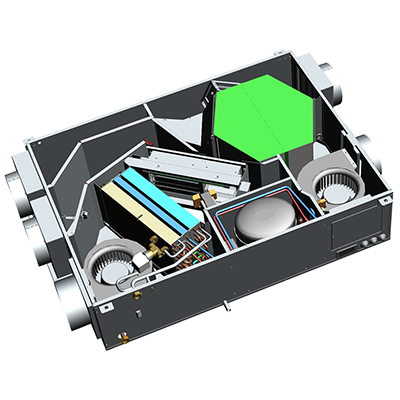

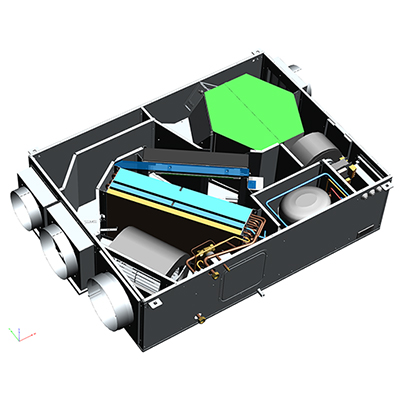

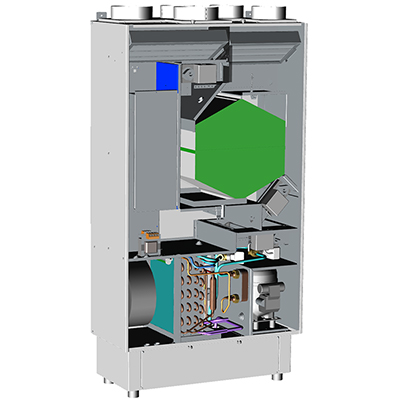

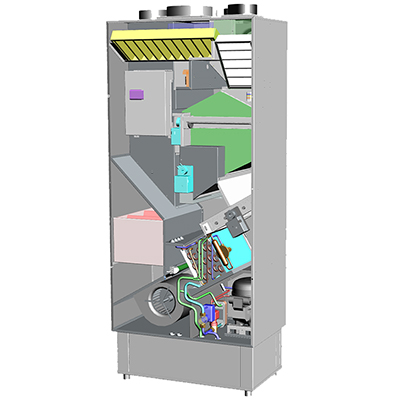

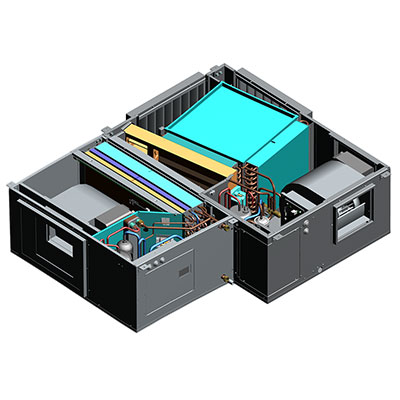

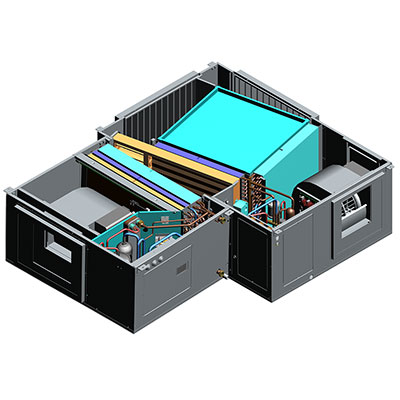

The fire-resistant Leonardo system consists of a 15 mm gypsum board panel laminated with 50 mm of high-density, A2-s1, d0 fire reaction class (UNI EN 13501-1) glass fiber, for a total thickness of 65 mm. The plasterboard panel is complete with 5-layer polyethylene piping with EVOH oxygen barrier. The MidiX Plus high-temperature-resistant polyethylene piping, with 5.5 or 10 cm spacing, is arranged in a serpentine pattern so as to maximize the exchange surface between piping and plasterboard. It is ideal for both winter heating and summer cooling.

.jpg) | SMART RADIANTThe smart and easy-to-manage systemEurotherm radiant systems are equipped with management technology that is as advanced as it is simple to use. The radiant system has never been so smart. |

|---|

TECHNICAL DATA SHEET

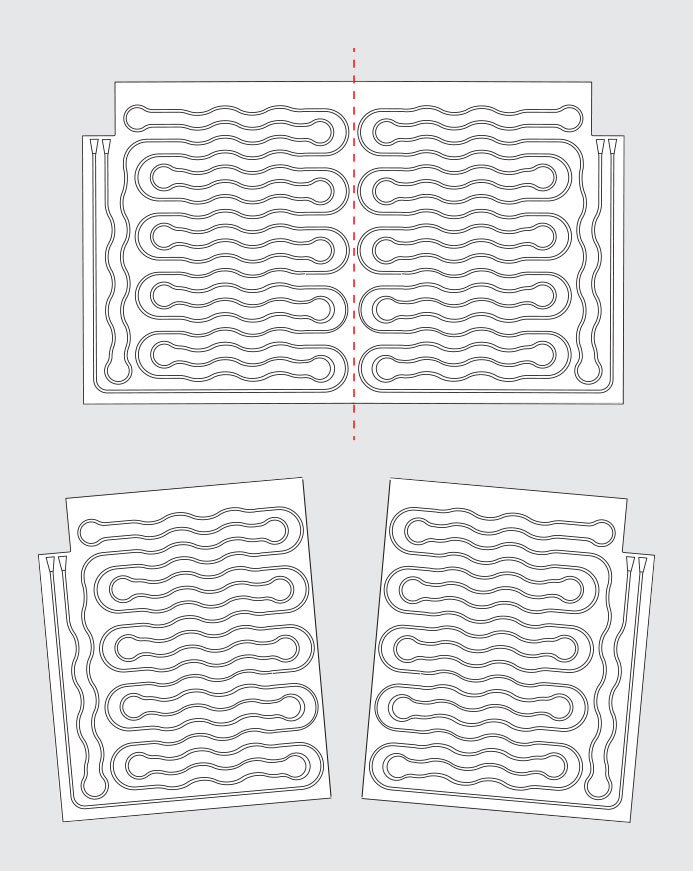

Pre-finished 15 mm plasterboard panel for ceiling installation coupled with 50 mm high-density glass wool with fire reaction class A2-s1,d0 (EN 13501-1), compressive strength 40 KPa (EN 826), having declared thermal conductivity λD of 0.037 W/m·K, complete with 5-layer MidiX Plus type II high-temperature resistant polyethylene PE-RT piping (DIN 16833, ISO 24033, ISO 22391, ISO 21003, EN 1264) with EVOH oxygen barrier in the pipe wall and vapor permeability of less than 0.32 mg/(m²d) at 40°C and 3.6 mg/(m²d) at 80°C (within DIN 4726 and EN 1264-4 limits), class 4 and 5 mechanical strength characteristics at 6 bar (ISO 10508) and an expected service life of 50 years; MidiX Plus 10 x 1.3 mm pipe arranged in a serpentine pattern with an optimized path to increase the safety area for fixing and 5.5 and 10 cm spacing; to ensure constant product quality, MIDIX PLUS pipe is subject to product and process verification and control by third-party body KIWA N.V, and supplied with KOMO K 86478 and DIN CERTCO 3V399 PE-RT system certification and CE marking through ETA 17-1013; there is a laser drawing on the surface of the panel indicating the position of the pipe; piping complete with rings for connection; the insulation layer houses a 20 x 2 mm (EN ISO 21003) PE-RT type II (PE-RT II/AL/PE-RT II) multilayer pipe bar, capped, pre-expanded and complete with rings for hydraulic connection of the panels to the main adduction lines, with class 1, 2, 4 and 5 mechanical strength characteristics at 10 bar, it is impermeable to oxygen as per DIN 16836 and meets the requirements of EN ISO 11855 and UNI EN 1264-4, with hydraulic connection air-tightness certification in accordance with EN ISO 21003-5. Smooth finish. Specific weight in service: ~18.3 kg/m² (10 cm pitch) and ~13 kg/m² (5.5 cm pitch).

Low thermal inertia

Thanks to the diameter and thickness of the pipe used (MidiX 10x1.3 mm), the fact the piping is integrated in the plasterboard, which increases the yield by 8% compared to the pipe inserted in the insulation, and the special serpentine geometry, the Leonardo ceiling system with guarantees high yield a very low system thermal inertia.

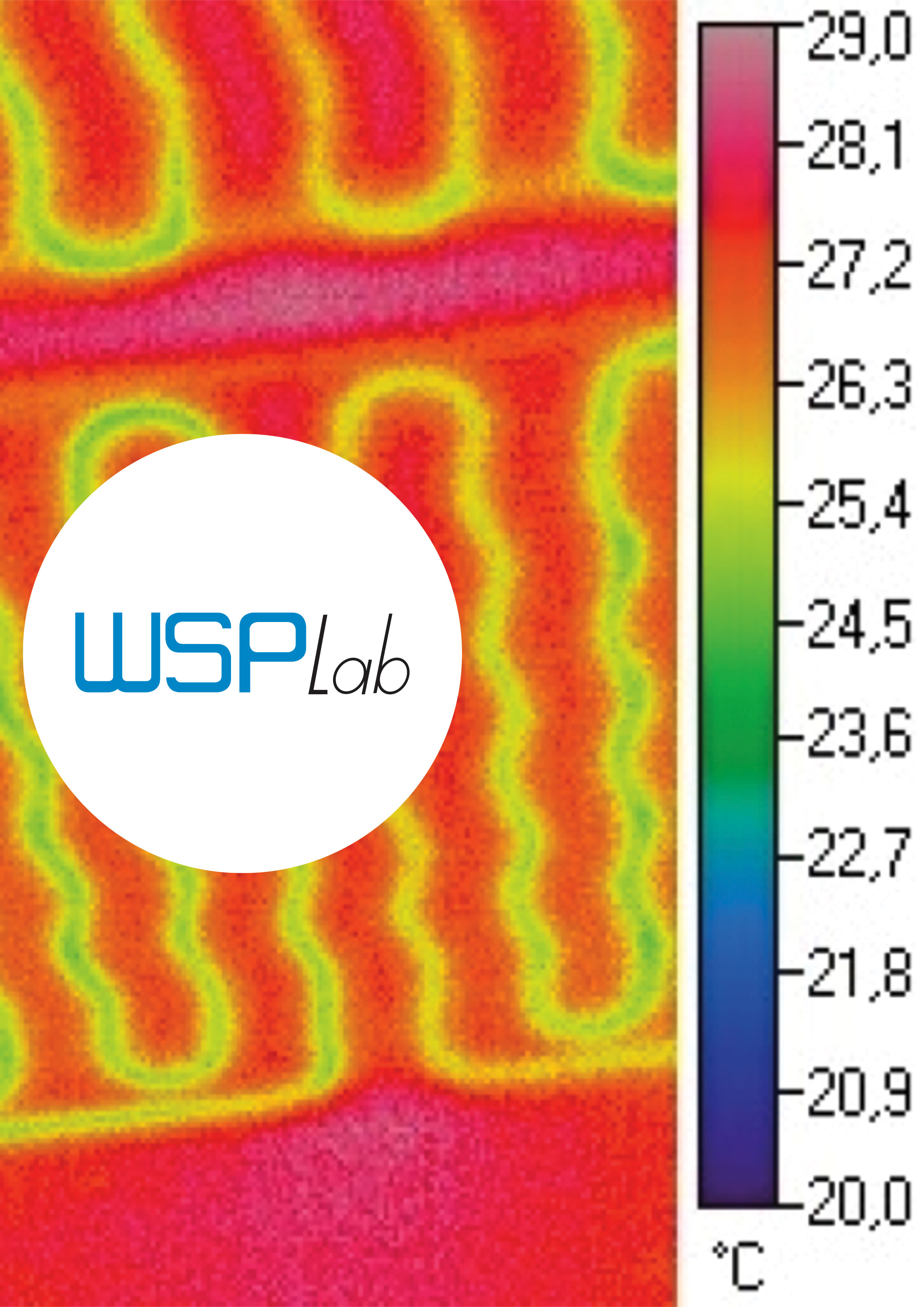

The adjacent thermographic photographs illustrate a Leonardo system operating in cooling mode at an average water temperature of 18° C. Note how, after just 20 minutes, the system is already operating at full capacity.

Lifetime warranty

Eurotherm radiant systems safer and guaranteed without time limit by ITAS insurance. Eurotherm now offers a full lifetime warranty original parts and breakdown warranty on its entire radiant systems range.

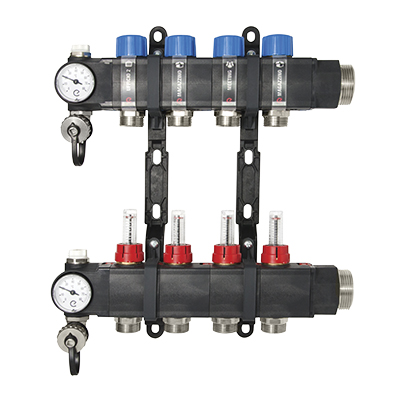

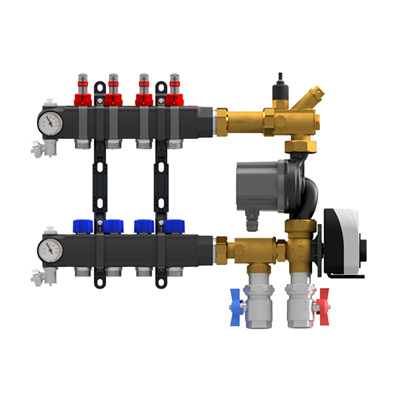

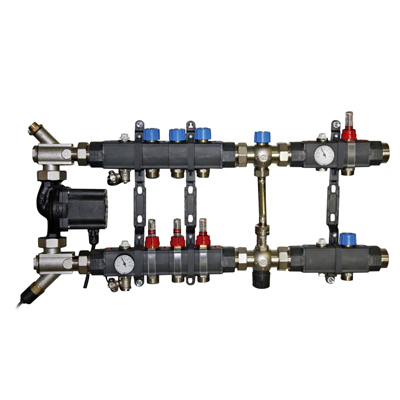

compose your system

Can't find the solution for you in the bundles?

Create your own system by selecting the components you prefer.

SELECTED PRODUCT