ACOUSTIC DESIGN

REGULATIONS AND CRITICAL ISSUES IN ACOUSTIC DESIGN

Acoustic performance depends on good building acoustic design, the choice of materials and, above all, their correct installation. The designer has at his or her disposal a series of regulations that make it possible to predict the results of the choice of one material or component (e.g. a window or doorframe) over another through calculation, and a series of data declared by the manufacturer following laboratory tests.

In addition, by means of on-site measurements, it is possible to establish whether the actual measured data reflects the data predicted at the design stage. Responsibility for the result, i.e. for achieving a building with adequate acoustic performance, is therefore the responsibility of the designer, the manufacturer of the materials and the contractor carrying out the work.

The need to highlight the individual acoustic parameters led to the definition of the acoustic classification of building units as described in UNI 11367 and UNI 11444.

STANDARDS FOR THE VERIFICATION OF ACOUSTIC PERFORMANCE IN THE LABORATORY AND IN SITU

A first distinction between methods for the experimental verification of acoustic parameters in buildings is between laboratory tests and in-situ tests, i.e. tests performed in the completed building.

The ISO 10140 series of standards describe laboratory test methods for measuring airborne sound insulation and impact sound pressure levels.

The ISO 16283 series of standards describe methods for assessing the properties of airborne sound insulation, façade sound insulation, and impact sound pressure level through in-situ measurements.

EN 29052-1 allows measurement of the dynamic stiffness per unit area of a resilient material, a useful value for estimating the impact sound pressure attenuation performance.

The ISO 354 standard allows the sound absorption performance of materials to be evaluated experimentally.

STANDARDS FOR THE CALCULATION OF BUILDING ACOUSTIC DESIGN

The standards of the ISO 12354 series can be used for the acoustic design relating to the passive acoustic requirements of buildings.

UNI EN ISO 12354-1 concerns the prediction of the apparent soundproofing power of a partition, R', (wall or ceiling) from the soundproofing power, R, (laboratory or theoretical value) of the surrounding partitions.

A direct path and three types of lateral path of sound waves through joints between elements are identified:

- D-d: direct path through the partition

- F-f: path from the side partition to the adjacent side partition

- F-d: path from the side partition to the separating partition

- d-F: path from the partition to the side partition.

Between two rooms, considering four joints, there are thus twelve lateral and one direct path. Lateral transmissions are one of the causes of a drop in performance between the values measured in the laboratory and the values measured on site, to this drop must be added any installation errors, plant installation, etc.

UNI EN ISO 12354-2 concerns the prediction of the normalised impact sound pressure level of floors, L'n, starting from the normalised impact sound pressure level and the soundproofing power, R, obtained in the laboratory or through theoretical evaluations of the surrounding partitions. Lateral transmissions through joints between elements are also identified in this case.

Between two overlapping rooms there are four side paths and one direct path, between adjacent rooms there are two side paths. Therefore, footfall noise between adjoining rooms must not be neglected.

UNI EN ISO 12354-3 concerns the prediction of the façade insulation, D2m,nT, starting from the knowledge of the soundproofing power (walls and window frames), R, and the insulation of small elements (shutter boxes, ventilation holes), Dn,e, obtained in the laboratory. The shape of the façade is then taken into account with the term ΔLfs, the dimensions of the receiving room and lateral transmissions.

ACOUSTIC DESIGN IN CONSTRUCTION: RESPONSIBILITY FOR THE RESULT

The acoustic properties of a building are verified in situ and involve all those involved.

.jpg)

ACOUSTIC CLASSIFICATION REGULATIONS VALID IN ITALY

These two Italian regulations concern the acoustic classification of building units with serial and non-serial characteristics. There is currently no specific European or international technical standard.

UNI 11367:2010 STANDARD

ACOUSTIC CLASSIFICATION OF BUILDING UNITS

The acoustic classification of building units, based on measurements taken on completion of the building, was created to enable future users to be informed about the acoustic characteristics of the building.

During the design phase, it is particularly important to carry out a forecast study of the passive acoustic requirements that can best estimate the performance to be found on completion of the work. In this regard, the indications of the UNI EN 12354 series of standards and the UNI/TR 11175 technical report can be used.

The UNI 11367 standard establishes an acoustic classification with reference to each of the requirements and for the entire building unit.

No acoustic classification is provided for building units for agricultural, craft and industrial use.

Living space: a portion of a building unit completely delimited and intended for the living and permanence of persons for the performance of activities foreseen by the intended use.

Accessory or service environment: a portion of a building unit with a function other than living, not intended for the performance of activities envisaged by the intended use. Accessory rooms are spaces intended for connecting living spaces and for horizontal and vertical distribution within the building system and spaces intended for storage, warehousing and garaging. For example, service rooms are lift shafts, stairwells, toilets, technical rooms in buildings, storage rooms, even inside the living unit, etc.

Acoustically verifiable room: a living space of sufficient size to allow measurements to be made in accordance with technical measurement standards.

The standards of the ISO 16283 series provide for room volumes from 10 m3 to 250 m3.

Technical element: vertical internal partitions, horizontal internal partitions, facades delimiting and conforming the interior rooms of the building, continuous or discontinuous functioning plant elements serving the interior rooms.

Façade: enclosure of a room that delimits the internal space from the external space; it may be horizontal, vertical or inclined and is generally characterised by the presence of opaque and transparent elements, with or without elements for shading, ventilation, security, control or other external equipment.

Continuous functioning system: fixed system whose sound level emitted over time is essentially constant; heating, air-conditioning, air exchange, forced extraction systems fall into this category.

Discontinuous operation system: fixed installation whose sound level emitted over time is not constant and is characterised by short periods of operation compared to the idle time during the course of a day; this includes sanitary installations, exhaust systems, lifts, goods lifts and automatic locks.

Building work: any work or work that changes all or part of an existing building or leads to the construction of a new building.

Corrected noise level of continuously operating equipment Lic: A-weighted equivalent continuous sound pressure level, corrected for reverberation time and residual noise.

Corrected noise level of discontinuous operating installations, Lid: maximum value of the A-weighted sound pressure level, acquired with time constant ‘slow’, corrected for reverberation time.

PROCEDURES FOR VERIFYING THE ACOUSTIC PERFORMANCE OF BUILDING UNITS FOR NOISE CLASSIFICATION PURPOSES

The acoustic verification may require a selection procedure for the structures and installations to be assessed. The verification for the purpose of acoustic classification following a building intervention must be carried out under conditions of finishing of the rooms and technical elements suitable for the verification itself.

If it is not possible, for a given technical element, to carry out the measurements required by the standard, the technical element is not verifiable.

NOISE CLASSIFICATION PER REQUIREMENT AND PER BUILDING UNIT

The determination of the value of a requirement is obtained through measurements for each of the measurable technical elements. In order to classify a building unit by requirement, the following procedure is followed:

(a) all the verifiable technical elements of the building unit are identified

(b) for each identified component, the useful value is determined, i.e. the value of the relevant requirements corrected with the measurement uncertainty

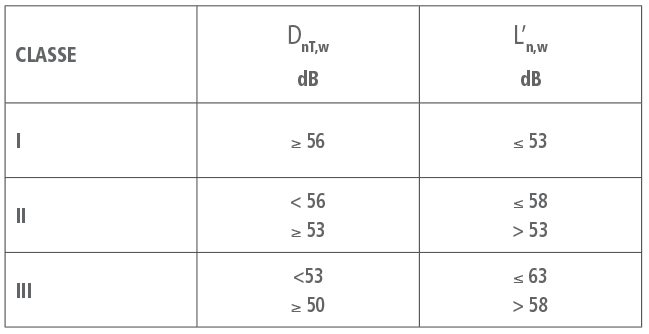

(c) the correspondence between the acoustic performance class and weighting factor Z according to the table is established for each requirement of the building unit:

In Italy, the noise level of technological systems is regulated by the decree D.P.C.M. of 5/12/97, which, however, does not provide a clear explanation of how to carry out measurements and has gaps in the survey methodology.

The UNI 11367 standard, on the other hand, defines the limits of the noise level emitted by continuous operation systems (such as ventilation, air conditioning, heating systems) and discontinuous operation systems (characterised by short periods of operation, such as lifts, exhaust systems). The noise level of continuous systems, with the same acoustic class, is lower than that of discontinuous systems and varies between 25 dB(A) and 37 dB(A).

For on-site noise measurement, there are common standards in Europe (EN ISO 16032 and EN ISO 10052), but there are also methods developed by each member country (such as the one indicated in UNI 11367, appendix D).

As far as limit parameters for noise performance in buildings are concerned, there is absolutely no common framework in Europe. Generally, the maximum sound pressure levels of installations vary between 25 dB(A) and 35 dB(A), although higher values are permitted in some rooms such as kitchens.

References

EN ISO 16032:2004

Acoustics - Measurement of sound pressure level of service equipment in buildings - Engineering method

EN ISO 10052:2004

Acoustics - Field measurements of airborne and impact sound insulation and sound of service equipment - Survey method

UNI STANDARD 11444:2012

ACOUSTIC CLASSIFICATION OF BUILDING UNITS

Guidelines for the selection of building units in buildings with non-serial characteristics

In the case of buildings with technical elements that are repeated according to patterns that depend on distributive, organisational and functional characteristics of the rooms of the building units (‘serial’ typology), UNI 11367 in appendix G foresees the possibility of adopting sampling criteria for each acoustic requirement, in order to reduce the number of tests. Such sampling is based on the identification of homogeneous sets of elements from which to derive the acoustic performance representative of the entire group and extendable to all technical elements with the same characteristics, adopting an appropriate sampling uncertainty.

In the case of non-serial building systems, UNI 11367 generally provides for the determination of the value of a given requirement through measurements for each of the measurable technical elements. This entails, in most situations, a very large number of tests to be carried out on site.

UNI 11444 provides guidelines for selecting those building units with non-serial characteristics that are most critical in terms of acoustic performance. For such building units, measurements of acoustic parameters can be made in order to determine their acoustic classification, based on the procedure described in UNI 11367.

In general, a number of building units not less than 10% (approximated to the integer by excess) of the total number of building units in the building system is selected, and in any case not less than two (for building systems up to four building units) and not less than three (for building systems up to thirty building units).

For the selection of the most critical building units, all critical building elements and installations within the building system must be taken into account. If some criticalities are repeated in several building units, those with the highest number of criticalities are to be classified.

In the event that some building units are built with different types of construction (e.g. internal walls made of coated gypsum plasterboard instead of masonry, or predalles type ceilings instead of laterocement type ceilings), these units must be subject to further specific measurements.

At the end of the measurements, the surveyor technician declares the acoustic classification of only those building units subject to measurement on the basis of the methodology described in UNI 11367.

CRITICAL ISSUES FOR ACOUSTIC DESIGN IN CONSTRUCTION

Critical issues for sound insulation of vertical and horizontal internal partitions (in no particular order of importance)

1) Structural lateral transmission: walls delimited by lateral structures (walls and floors, screeds) continuous without interruptions (beams, pillars, elastic joints, etc.); greater criticality for situations in which the perforation of the lateral structure is perpendicular to the wall; walls located in habitable attic spaces.

2) Presence of lateral air transmission paths: walls between habitable rooms of two building units, bordering laterally with accessory rooms for collective use, such as stairwells/elevator rooms and communicating with these through doors.

3) Particular integration with plant systems: rooms connected by technological systems (such as adjacent extractor hoods, boxes of opposing and connected electrical systems, ducts, conduits, etc.), walls partially or completely crossed by plant elements.

4) Ducts: presence of plant ducts connecting the emitting and receiving environments (for example, mechanical ventilation systems with ducts common to the two environments or kitchen ventilation hoods).

5) Cavities: presence of plant-engineered cavities that connect two rooms.

Critical points for the level of impact noise

1) Surface finish:

stiffer materials (ceramic, stone and others) generally result in worse performance than more resilient finishes (wood and others)

stiffer skirting boards (ceramic, stone and others) generally result in worse performance than more resilient skirting boards (wood and others)

2) Type of room distribution: presence of entrance door or French window in the source room, irregular source room (presence of niches, corners, etc.) due to difficulties in creating the floating screed.

3) Extent of lateral transmissions:

- presence of through cavities

- adjacency to stairwells and lift shafts

- presence of plant ducts connecting the transmitting and receiving environments.

Criticità per l’isolamento acustico di facciata (dal più critico al meno critico)

1) Type of window frame, shading system exists but ventilation

- shutter systems with shutter box that can be inspected from the inside and/or with air passage devices integrated in the frame or masonry

- greater number of sashes; fewer gaskets

- stratigraphy of the window and door glazing.

2) Sserr /Sopaca ratio: greater ratio between the surface area of the window frame (Sserr) and the surface area of the opaque part (Sopaca).3) Room form factor (Sfacc /Vamb): greater ratio between the surface area of the façade (S) and the volume of the room (Vamb).

4) Facade form factor (ΔLfs): façades with reflective surfaces above or to the side of the window and, among these, those without a sill or with an open sill.

Critical points for noise from discontinuous operation installations

1) Presence of plant crossings (cavities) adjacent to inhabitable and acoustically measurable rooms.

2) Presence of rooms adjacent to toilets with WC and cistern connected to the partition wall.

3) Presence of adjacent rooms with mechanical installations or motorised openings.

Critical points for noise from discontinuous operation installations

1) Presence of plant crossings (cavities) adjacent to habitable and acoustically measurable rooms.

2) Presence of adjacent rooms with toilets and cisterns connected to the partition wall.

3) Presence of adjacent rooms with mechanical installations or motorised openings.

Critical issues for noise from continuously operating systems

1) Presence, in adjacent rooms, of components and terminals of air conditioning or ventilation systems serving other building units or the whole building system not adequately insulated.

2) Presence, in adjacent ancillary or service rooms, of continuously operating systems or components of systems (pumps, fans, etc.) serving other building units or the whole building system.

NOTE

Heating and cooling systems, both radiant and non-radiant, can generate slight noises lasting a few seconds (tichettii) when being switched on in heating or cooling mode due to the expansion of materials. They may or may not be perceptible depending on their positioning in the structure and the background noise.